Packaging Support Drives Development, Design, and Production | Consumer Electronics

12/19/2019 RRD

Innovative Design for CE Packaging Plays Major Role in Product Launch

CHALLENGE

Rylo, a California-based technology company, had plans on taking a new, innovative consumer electronic to market: its compact 360-degree video camera. With these plans came a need for equally innovative packaging.

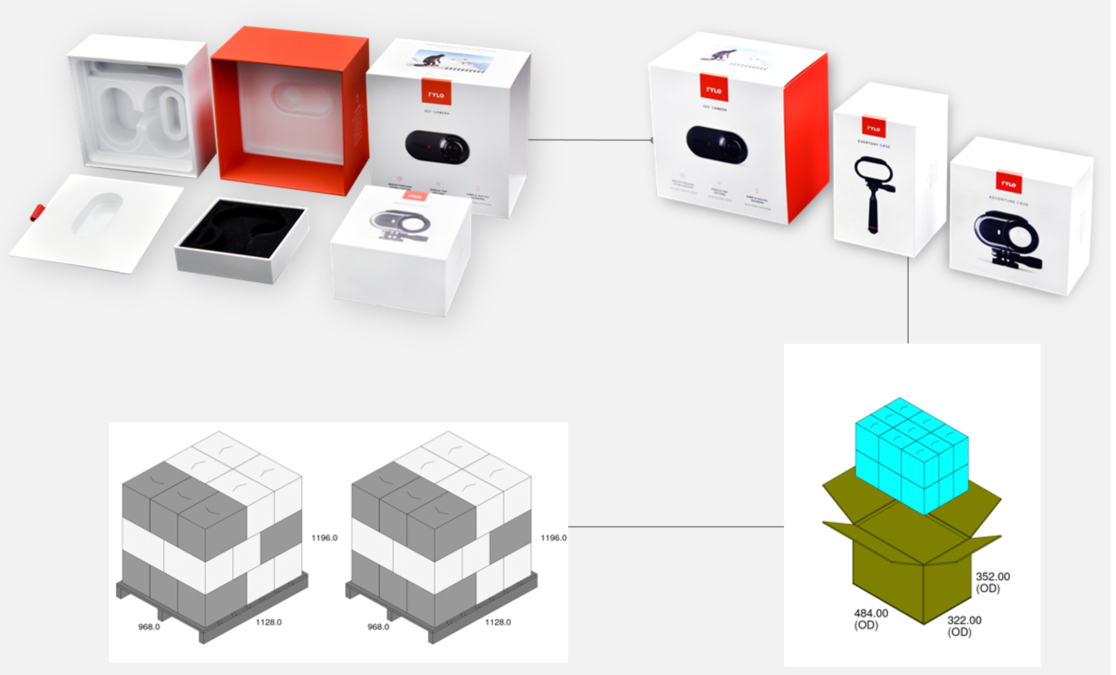

Going to market, Rylo’s packaging requirements included a box (and accessory boxes) that reflected the quality and thoughtfulness of its product. In short, the final design needed to be simple, elegant, easy to understand, and easy to open.

The tech company turned to RRD for packaging support in three key areas: development, design for manufacturing, and production.

SOLUTION

RRD led a design process that proceeded quickly over just a few months, and involved several iterations. The process included:

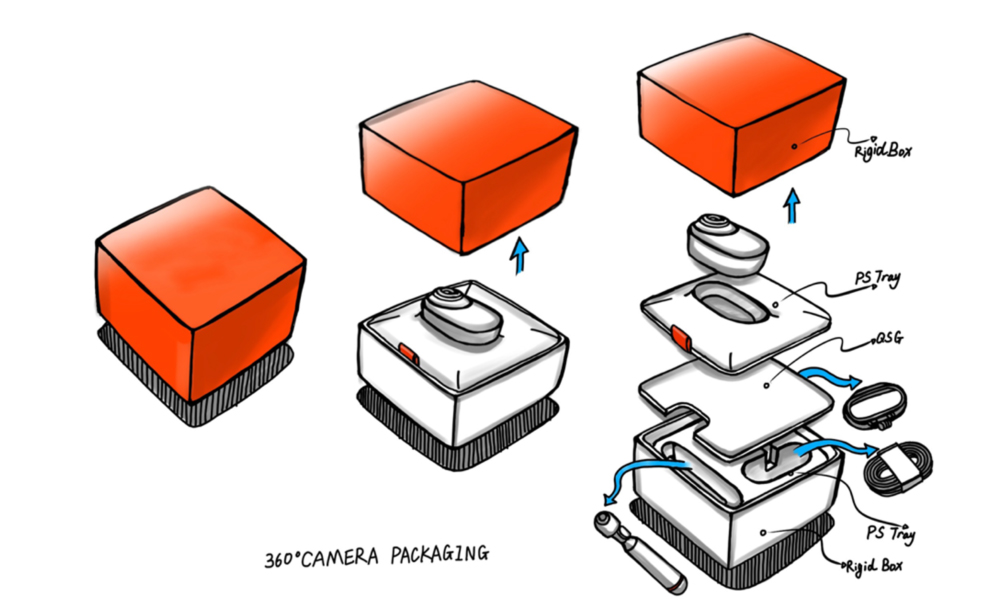

1. Industrial design (sketching and 3D rendering)

2. Packaging engineering (technical drawings for prototyping, material selection, and performance and testing consideration)

3. Mechanical design (e.g., foam, tray, paper insert)

4. Prototyping

5. Shipping and container optimization

Through blank-white prototypes and redefined material specifications, RRD helped Rylo meet both cost targets and design aspirations. For example, RRD produced a box at a cost lower than the client anticipated, which optimized their budget to now allow for the use of higher-end finishes. RRD added a soft-touch matte lamination on the top and bottom of the box for a luxurious feel.

Additional box features included a rigid board top and bottom, polystyrene (PS) trays, satin ribbon, and EVA foam accessory holders.

RESULTS

RRD produced more than 50,000 boxes for Rylo’s innovative product. Along with the main camera box, RRD supplied stickers, commercially printed inserts, foams, the battery box, and two other accessory boxes.

RRD continued to gain client trust through quick turns and flexibility, often turning a full order around in less than four weeks and working closely with the client’s original equipment manufacturers (OEM) to manage the delivery and warehousing.

Within one year, RRD had developed generation one packaging and began production on generation two.