License Plate Labels Go Linerless to Reduce Costs, Increase Efficiency | Retail

10/26/2022 RRD

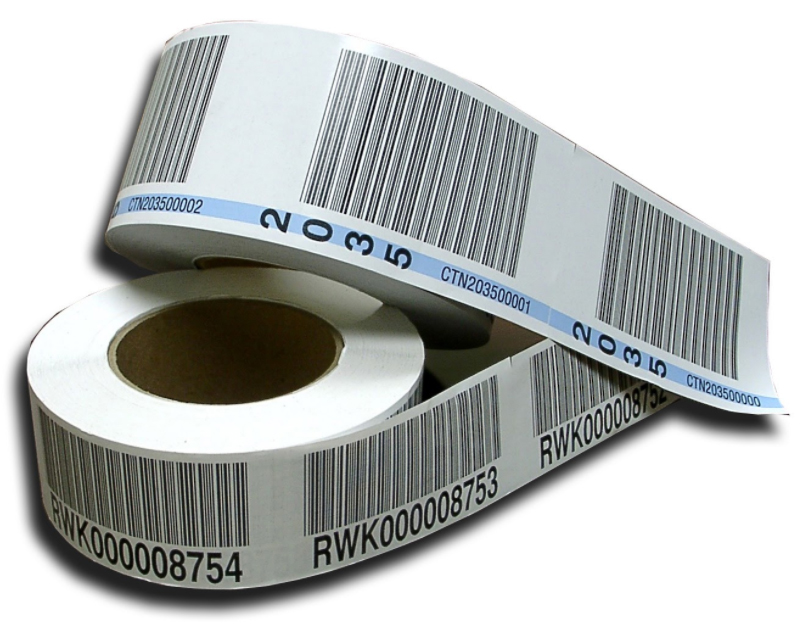

Major American brand benefits from smaller, variably printed VersaTac™ Liner-Free label rolls

CHALLENGE

The distribution and warehousing departments of a large retail chain had been printing 4” x 2” license plate labels on demand using thermal transfer printers. However, a new “chute” system was installed for product sorting and labeling, and there was no longer enough space to accommodate the printers.

One solution was to switch to pre-printed labels ready to be applied to the product, but this process required a cumbersome, time-consuming process of printing and re-rolling the labels. It also created a lot of messy liner waste on the floor, causing a safety hazard.

One solution was to switch to pre-printed labels ready to be applied to the product, but this process required a cumbersome, time-consuming process of printing and re-rolling the labels. It also created a lot of messy liner waste on the floor, causing a safety hazard.

SOLUTION

When RRD’s experts saw the new sorting system and came to understand the problems, they introduced their VersaTac™ Liner-Free linerless label product for consideration. Going linerless allowed the client to use fewer rolls overall, requiring less space and reducing the amount of restocking needed. A reduction in waste — less cores and fewer cartons used — aligns with sustainability goals as well.

RRD also suggested using variably imaged linerless labels so that labels did not have to be printed on demand.

RESULTS

RRD's VersaTac Liner-Free labels have addressed the operation’s inefficiencies in this client’s license plate label production. RRD’s variably imaged linerless labels are cost-effective, take up less room, and are easy to use. Results include:

- Reduced labor costs due to less restocking and elimination of printing/rerolling labels

- Reduced freight costs by about 30-40% compared to linered product

- Reduced safety risk because linerless labels have no liner to end up on the floor

United Ad Label, an RRD Company, assembled a comprehensive guide to thermal labels. Read The Only Guide You Need For Thermal Labels on UnitedAdLabel.com.