VersaTac Liner-Free™ Labels: FAQs Our Clients Asked Before Making the Switch

2/9/2026 Judy Marx

The FAQs our clients have asked about RRD's VersaTac Liner-Free™ linerless labels

The following are what we might categorize as “frequently asked” — and our answers to them cut right to the chase. (If you’d like to talk about any of these at length, just let us know.)

- Why go linerless?

- Will switching to linerless labels have any effect on my business’s operational costs?

- Is the process of converting to linerless time-consuming and expensive?

- Are RRD's VersaTac Liner-Free™ linerless labels a more eco-friendly option?

- How do we get started on a linerless strategy?

- Where can I buy VersaTac Liner-Free labels online?

- Does a lack of liner affect a label’s durability or adherence to surfaces?

- Are the adhesive options limited when it comes to going linerless?

- Is there anything else I should know about linerless labels as I evaluate my labeling options?

- Do you have any client success stories you can share where linerless labels played an important role?

1. Why go linerless?

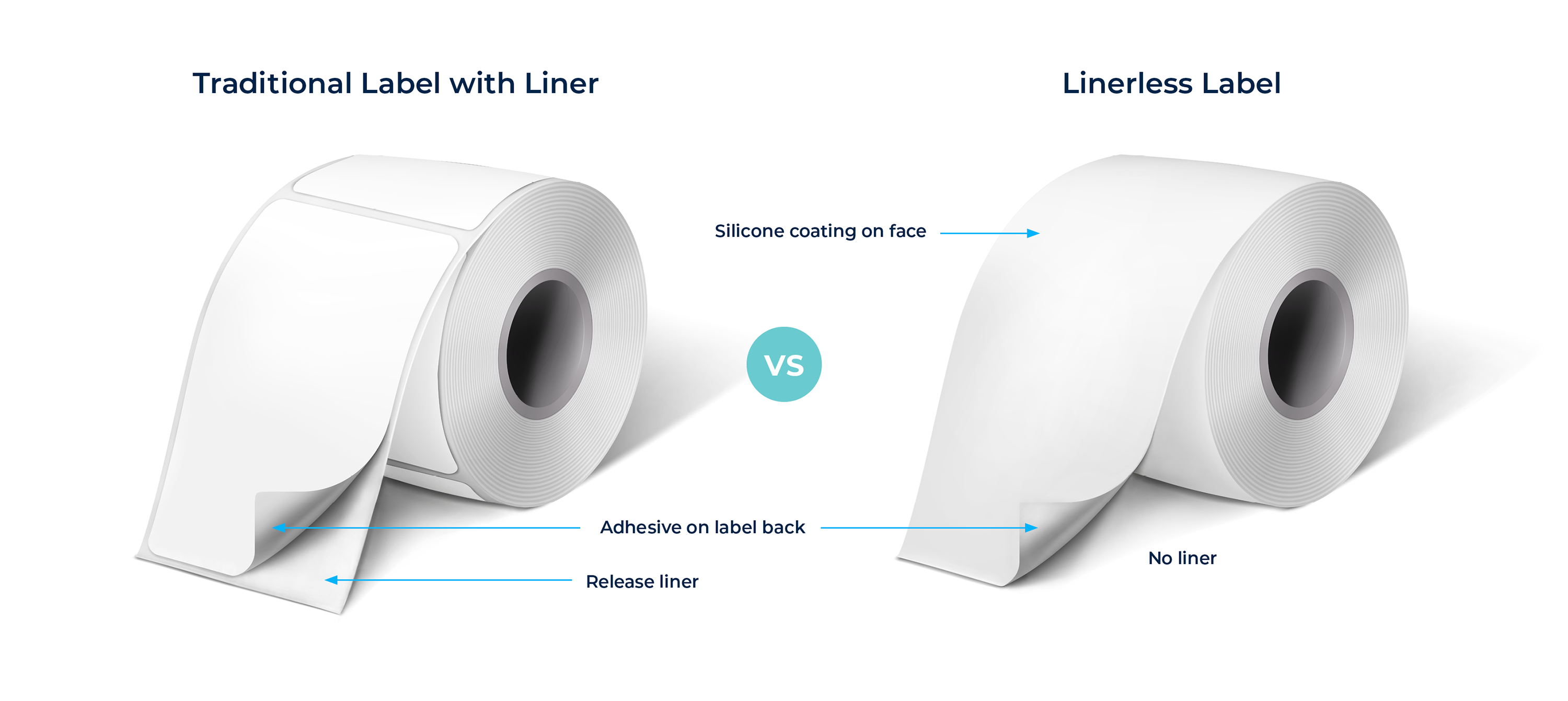

In a market where businesses find themselves getting pinched by material availability at every turn, labels have proven to be no exception. This is particularly true for conventional labels — those that utilize a liner, where the label is pulled off a silicone-coated backer.

For our clients, RRD's VersaTac Liner-Free labels, in many cases, have provided a more viable, more sustainable, market-ready option. And the current demand for them became a driving reason for our expansion into additional linerless manufacturing capabilities. This investment has helped us increase our capacity for direct thermal linerless label production by roughly 40%.

If you’re unfamiliar with the value proposition around linerless, look no further. RRD developed and patented this label type in the early nineties. As a pioneer in this space, we’ve answered a number of questions about linerless over the years.

2. Will switching to linerless labels have any effect on my business’ operational costs?

It's very possible. A linerless label’s reduced footprint increases the likelihood of the following:

- More labels, fewer rolls — up to 60% more labels per roll — which translates to a reduction in downtime required to change rolls

- Minimized costs through reduced freight, reduced warehousing space, and the elimination of liner disposal

- Improved workplace safety through the removal of slippery silicone liners that can end up on the floor, which can reduce downtime

3. Is the process of converting to linerless time-consuming and expensive?

Due to the unique material construction differences between standard linered labels and linerless options, making the transition to liner-free may require an investment in new equipment (e.g., new printers, platen rollers for dispensing labels, or modifying the firmware/software of each printer).

It's also important to note that regular thermal desktop and mobile printers do not accommodate linerless labels. These technology updates are the most common barrier to entry for many companies — and are why working with a labeling partner such as RRD for hardware compatibility guidance makes a good deal of sense.

We know that changing a process can be daunting, but as an end-to-end partner, RRD helps make implementation seamless. We have relationships with printer manufacturers to ensure full compatibility, and our R&D labs can test your specific application to ensure the label sticks perfectly. We also offer conversion programs to help you evaluate the ROI of switching hardware.

4. Are RRD's VersaTac Liner-Free linerless labels a more eco-friendly option?

RRD’s recent research, The 2026 Integrating Packaging Report, shows that packaging and labels decision-makers are prioritizing the advancement of their sustainability efforts despite ongoing economic uncertainty. If you are looking for a more sustainable labeling option, RRD's VersaTac Liner-Free labels are worth a closer look.

The silicone-coated backer pulled off your traditional label is typically non-recyclable. It’s really one of the biggest drivers of waste in a label’s lifecycle. And, because they contain silicone, label liners can’t be burned, and they also won’t decompose. Linerless labels remove the need for this backer, creating immediate sustainability benefits.

6. Where can I buy VersaTac Liner-Free labels online?

United Ad Label, an RRD Company, has VersaTac Liner-Free linerless in stock and available for immediate shipment. Visit the Linerless Labels page on the UAL website to learn more about what we offer and place your order today.

Place your order today

7. Does a lack of liner affect a label’s durability or adherence to surfaces?

We’ve had to debunk the myth (more than once) that the lack of a liner actually compromises a label’s quality. That’s just not the case. This is simply a leaner label.

The release coating used on a VersaTac Liner-Free label has been developed to not only prevent the adhesive from sticking to the labels beneath it but also to serve as a protective barrier against UV, moisture, and chemicals. This ensures durability and a longer shelf life.

8. Are the adhesive options limited when it comes to going linerless?

Absolutely not. At RRD, all of our VersaTac Liner-Free labels are available to run with CleanTac® (repositionable) adhesive, VersaTac adhesive, or permanent adhesives. Regarding the adhesive’s stickiness, that is determined by the adhesive pattern on the back of each label roll. Patterns can also vary depending on the application.

9. Is there anything else I should know about linerless labels as I evaluate my labeling options?

While linerless labels come in limited shapes (i.e., rectangles and squares), there is flexibility to be had in terms of label sizing. Unlike many conventional labels that are cut to a predetermined size, RRD's VersaTac Liner-Free labels can print multiple sizes of labels on a single roll — think shipping labels as well as separate barcode labels.

At RRD, our VersaTac Liner-Free label solution includes the option to add timing bars as a start /stop gap sensing mode and perforations, which increase efficiency for the end user with faster, easier, and cleaner tears. The product line is customizable and includes decorative linerless for glass, window, and door manufacturers.

10. Do you have any client success stories you can share where linerless labels played an important role?

These five case studies should help illustrate the beneficial role our VersaTac Liner-Free labels played for our clients’ businesses:

Judy Marx is a Business Development Manager for RRD Packaging and Labels.